position:Home > Products > Sheet metal deburring equipment

|

|

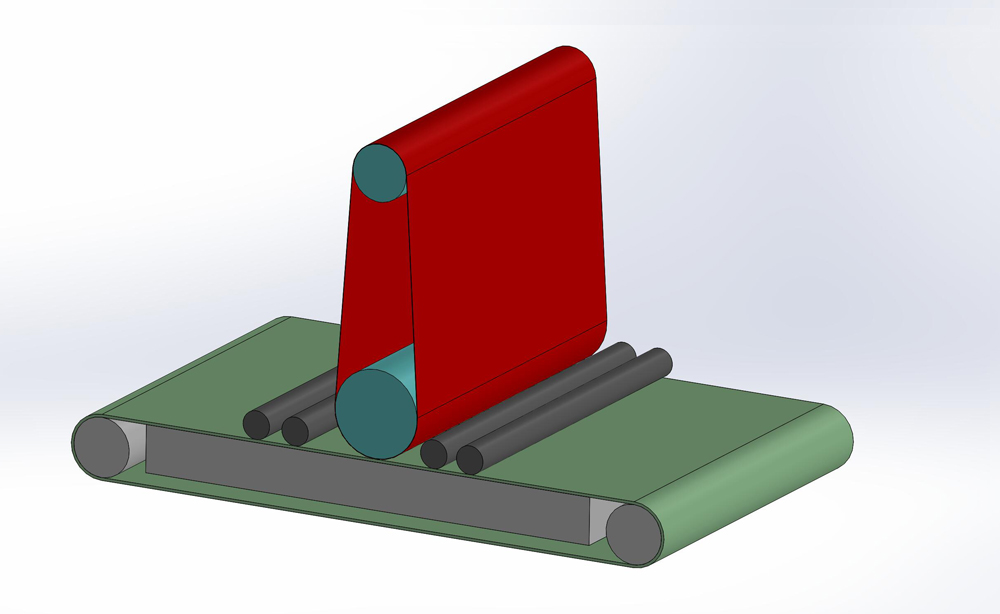

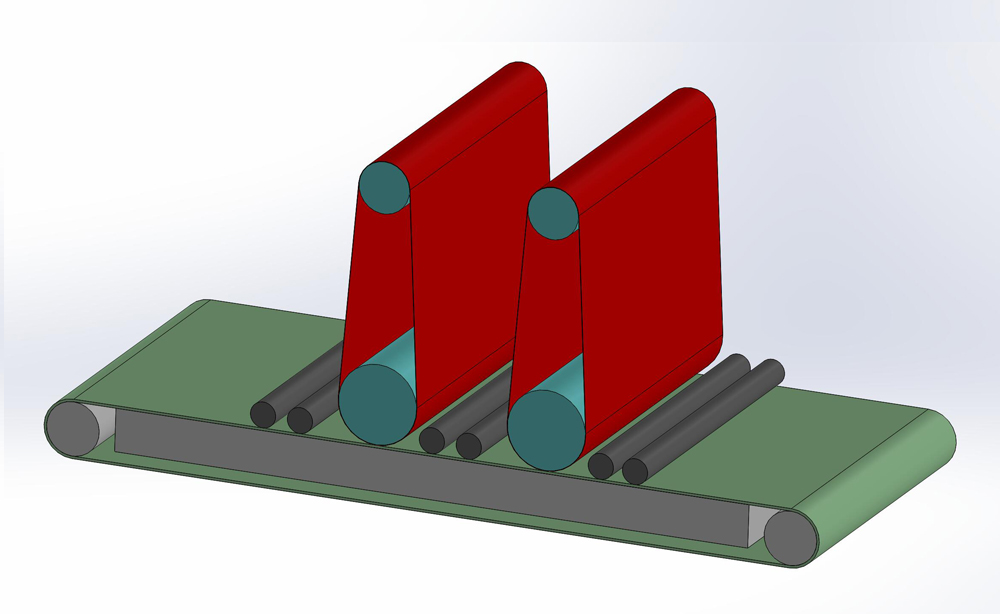

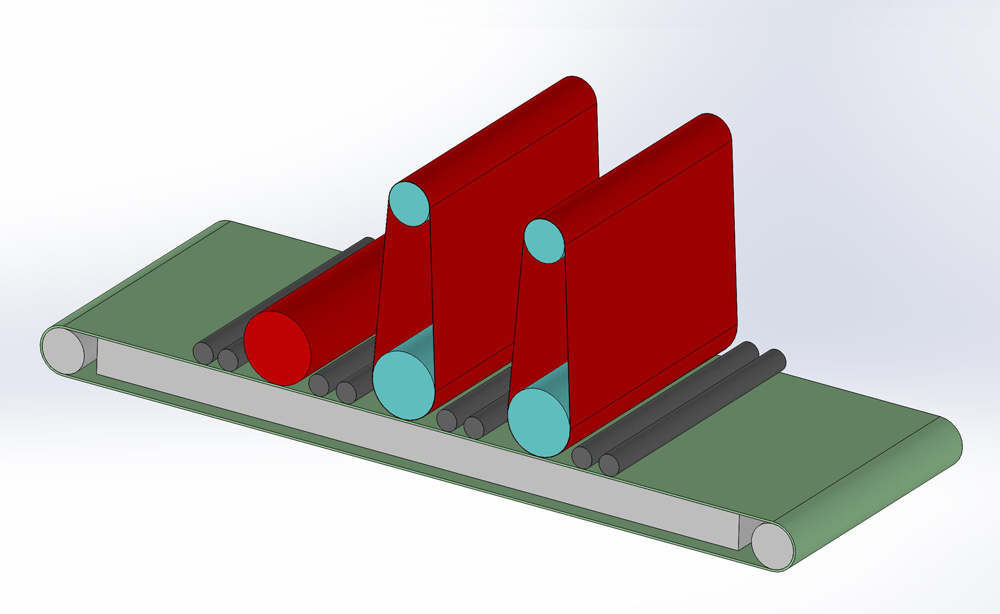

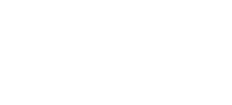

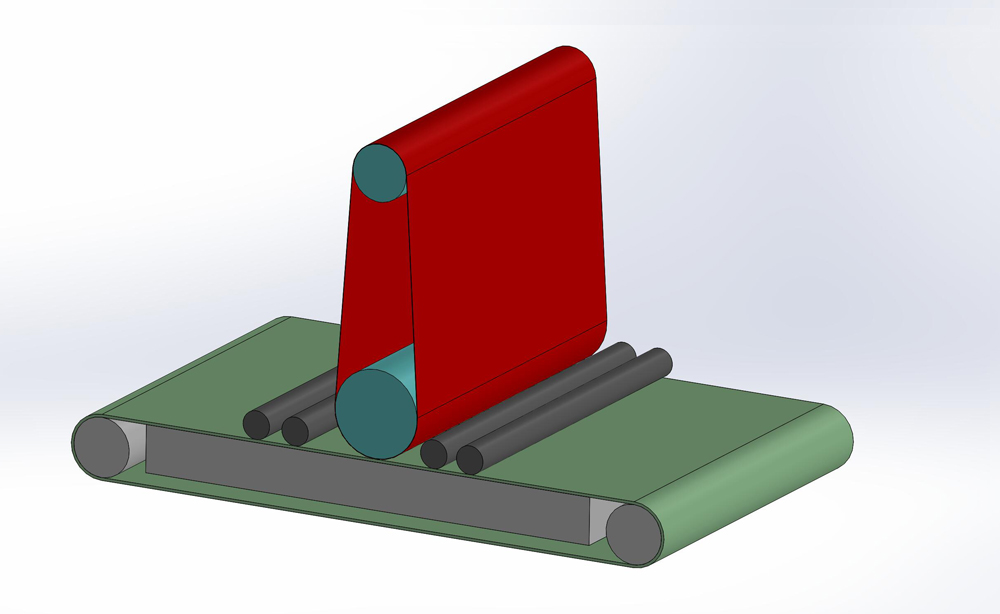

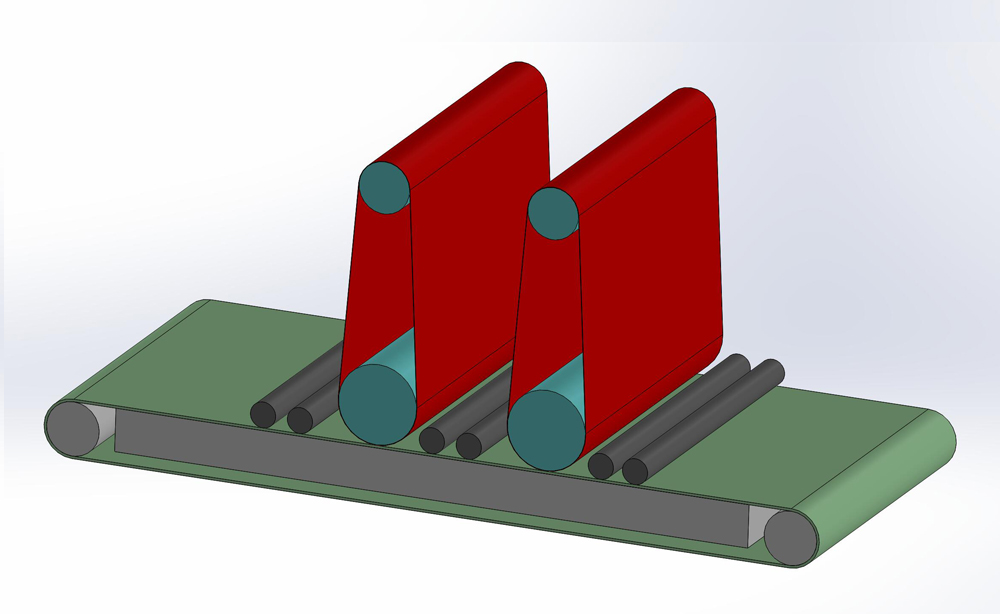

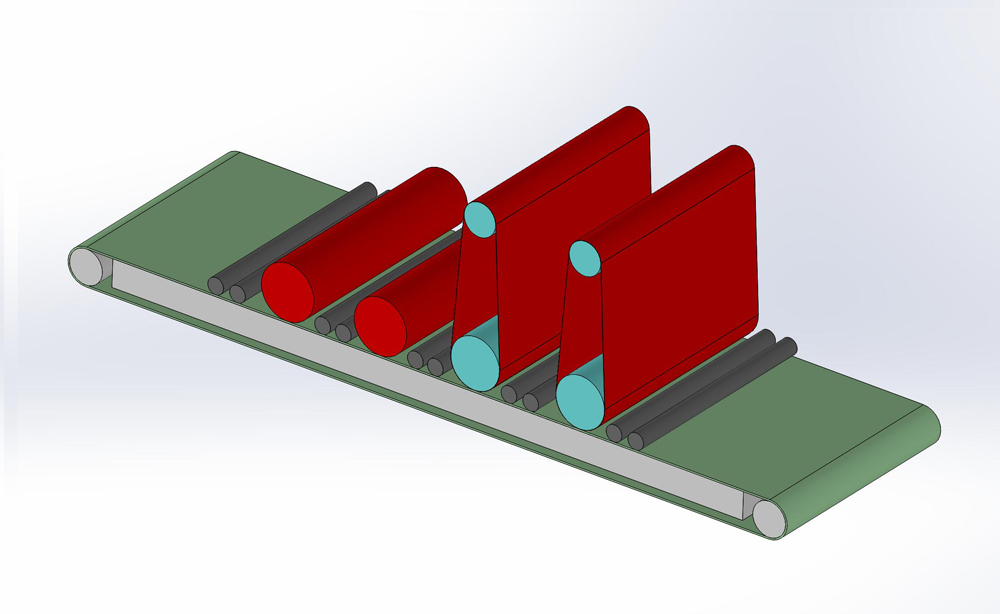

Dry grinding metal sander series |

Basic parameters of equipment:

1. Scope of application: Suitable for flat panel parts, carbon steel plate, stainless steel plate, aluminum plate, copper plate, titanium alloy, all kinds of non-ferrous metals, rubber and plastic materials, marble, graphite and so on.

2. Equipment function: Suitable for all kinds of flat plate parts surface drawing, polishing, scratch, remove longitudinal burr, oxidation skin, hair, fixed thickness and other processing.

3. Equipment combination: single or multiple combination structure of sand belt + polishing wheel

4. Equipment processing width: 350mm, 650mm, 800mm, 1050mm, 1350mm, 1600mm, 2000mm, 2200mm

5. Equipment processing thickness: 1-80mm

6. Belt line speed: 18m/s (optional frequency control)

7. Polishing wheel line speed: 20m/s (optional frequency control)

8. Feeding speed: 2-11m/min (variable frequency)

9. Optional feeding method:

(1) Conveyor belt + rubber press roller clip feed (suitable for ordinary workpieces. Workpiece length ≥280mm)

(2) Strong permanent magnet adsorption feeding (suitable for carbon steel workpieces. Workpiece size ≥10mm×10mm)

(3) vacuum negative pressure adsorption feeding (suitable for stainless steel plate, copper plate, aluminum plate, etc., is not magnetically adsorbed. Workpiece size ≥50mm×50mm)

(4) Rubber roller + rubber roller clip feed (suitable for large and heavy workpieces. Workpiece length Workpiece length ≥280mm)

10. Four-column synchronous lifting, lifting height digital setting and reading, unit mm

11. Supporting wet vacuum cleaner or industrial pulse vacuum cleaner to deal with grinding dust, to achieve environmentally friendly production.

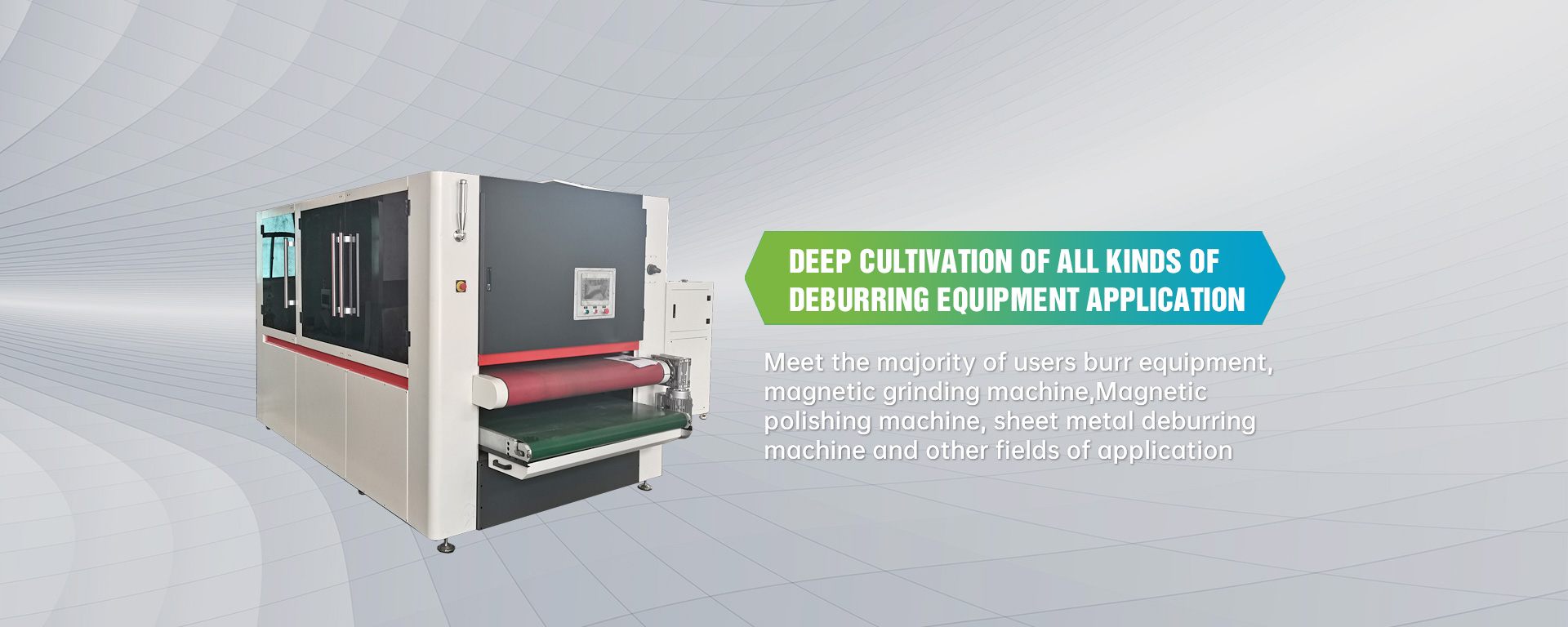

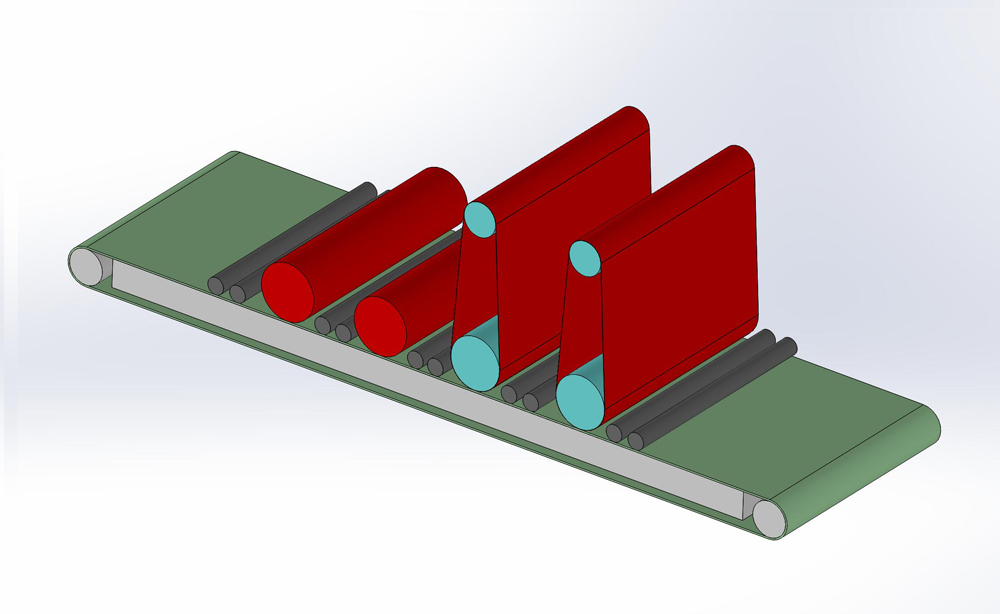

Equipment structure diagram:

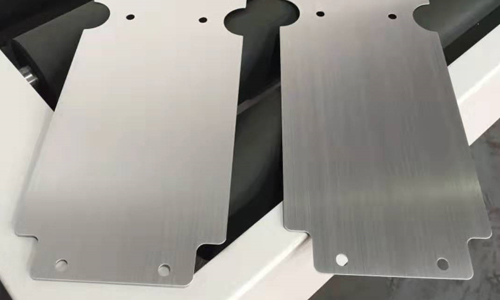

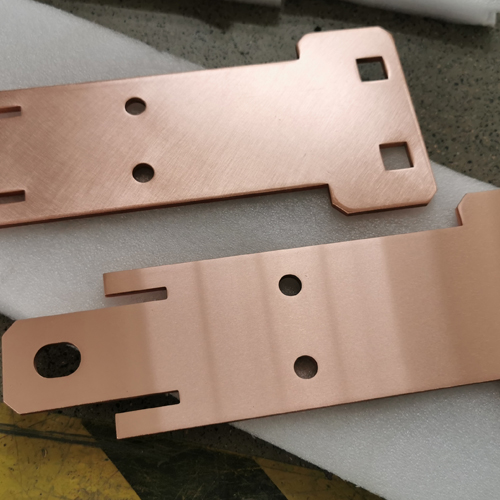

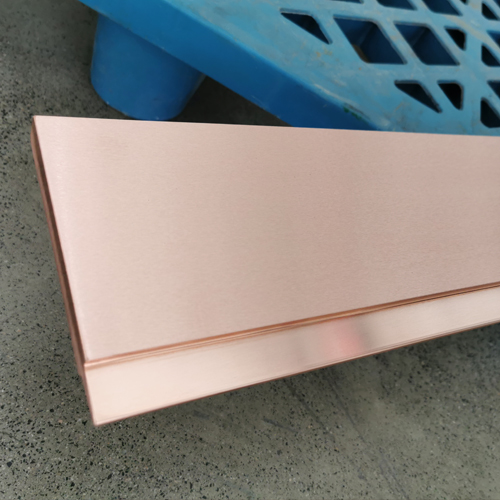

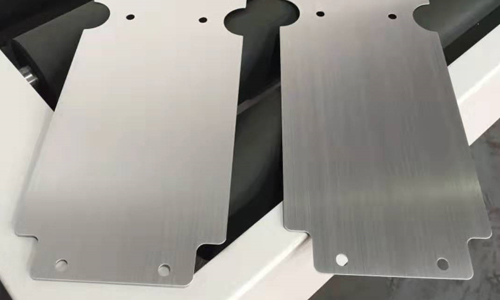

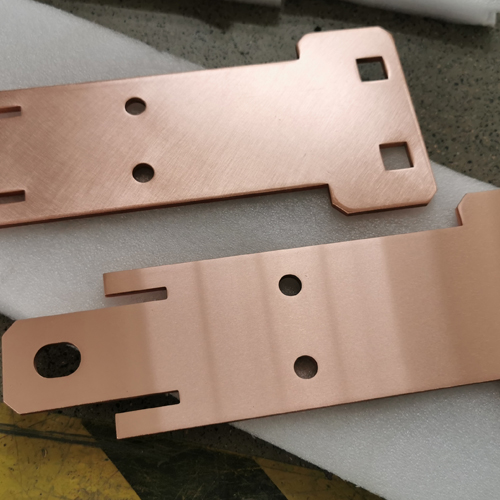

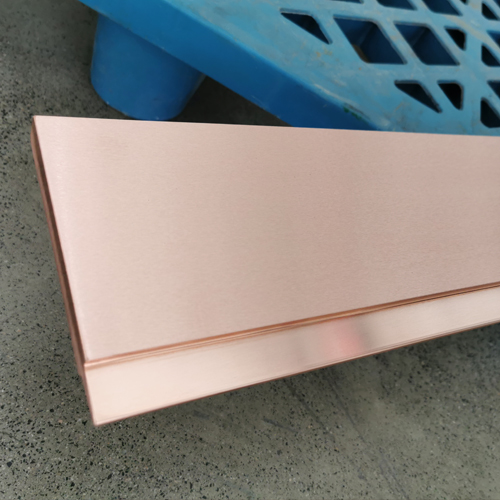

Equipment processing product diagram