position:Home > Products > Translation grinding/polishing machine

|

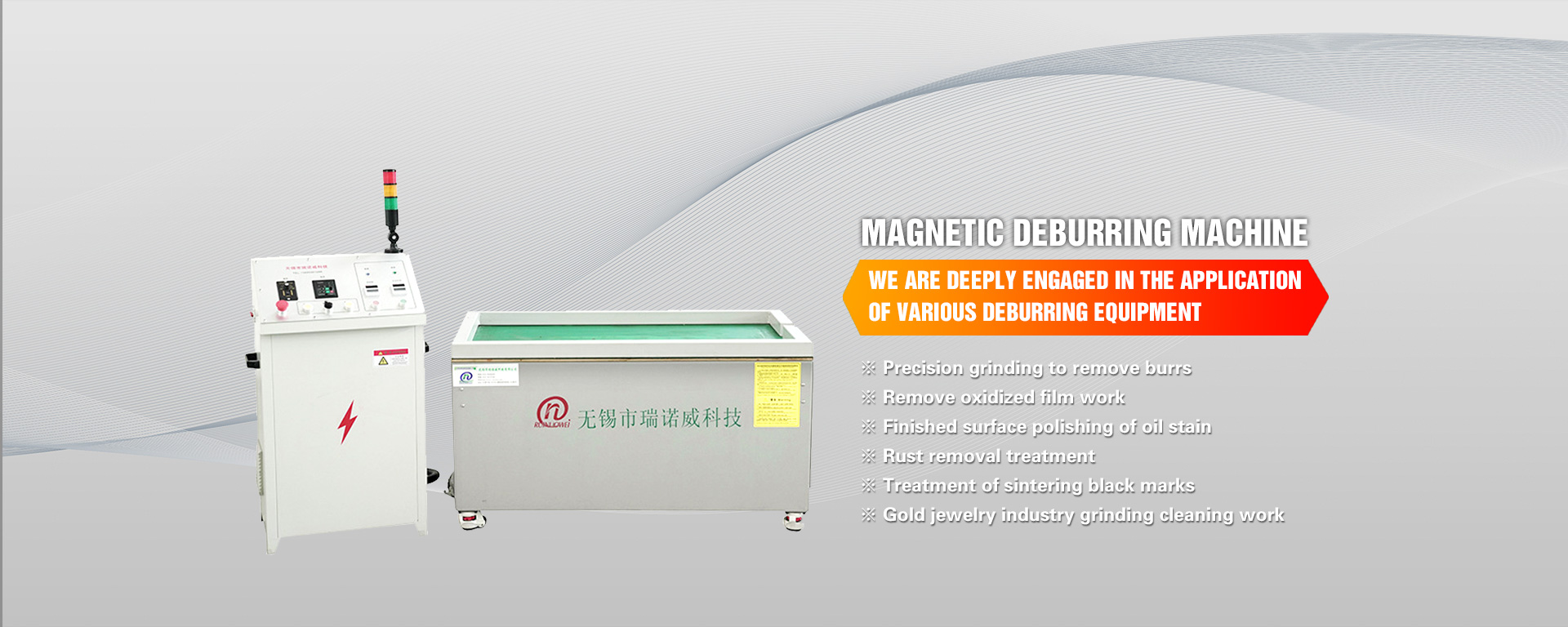

R-G1610 translation magnetic polishing machine |

| | Equipment type | R-G1610 | |

| | Power source | 380V | |

| | Motor power | 2.2KW*2(Optional) | |

| | Equipment size | 1800*720*1100mm | |

| | Groove size | 1600*620mm | |

| | Reference quantity large processing quantity | 30-40kg | |

| | Processing speed | 0-60HZ | |

| | Mode of operation | Forward and reverse rotation and translation | |

| | Machine weight | 480KG | |

Translation magnetic polishing machine advantages:

On the basis of the original magnetic polishing machine, the magnetic field of 2-3 units is moved around, which greatly improves the uniformity of the entire polishing, and the product has no blind area in the grinding barrel, especially the disk center and around the position.

Translation magnetic polishing advantages:

1, throw small pieces because there is no center and surrounding blind area, the word can greatly increase the processing weight, polished products uniform, higher efficiency.

2. High uniformity of large pieces, including brightness and sand surface, high uniformity of deburring. (The reason is that the large piece is too big to roll freely)

3, translation polishing machine on the basis of the original circular, because the left and right to move back and forth, greatly increased the length of the magnetic field area, suitable for throwing longer products.

Translation magnetic polishing machine is more suitable for large quantities of parts such as large, long tubes and complex parts of the deep hole, cavity hole deburring polishing, the processing surface, high quality requirements in the hole, manual and traditional ways can not be processed to the part, to achieve mass processing without damage to the workpiece, improve efficiency and quality, machine grinding without dead corners.

Translation magnetic polishing machine application scope:

· Cooling accessories copper, aluminum, stainless steel, etc. (can replace pickling, electrolysis)

· Stainless steel, copper, iron spot removal

· Precision stamping parts, small hardware parts

· Precision spring, shrapnel and other parts

· Machine walking, CNC automatic lathe and other parts

· Zinc alloy, aluminum radiator, aluminum alloy die-casting parts

· Aviation accessories, medical equipment, surgical instruments and other parts

· Electronic, computer, communication and other parts

· Rail transit, sheet metal industry, high-end kitchen appliances and other parts