position:Home > Products > Magnetic grinding/polishing machine

|

Magnetic polishing machine R-G12 |

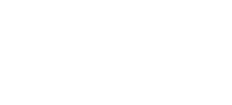

| | Equipment type | R-G12 | |

| | Power source | 380V | |

| | Motor power | 2.2KW | |

| | Equipment size | 740*620*1100mm | |

| | Groove size | 520*520mm | |

| | Reference quantity large processing quantity | 10-13kg | |

| | Processing speed | 0-60HZ | |

| | Mode of operation | Positive and negative rotation | |

| | Machine weight | 180KG | |

Magnetic polishing machine - is to use the power of the magnetic field to guide the grinding material (magnetic needle) to rapidly rotate and grind the workpiece to achieve the grinding effect of burring (batching front), surface polishing, cleaning, cleaning, oxidation film, sintering marks, rust and so on.

The surface of the workpiece is polished, polished and smooth

Parts do not collide with each other after grinding the product will not deform, never affect the accuracy, never damage the surface;

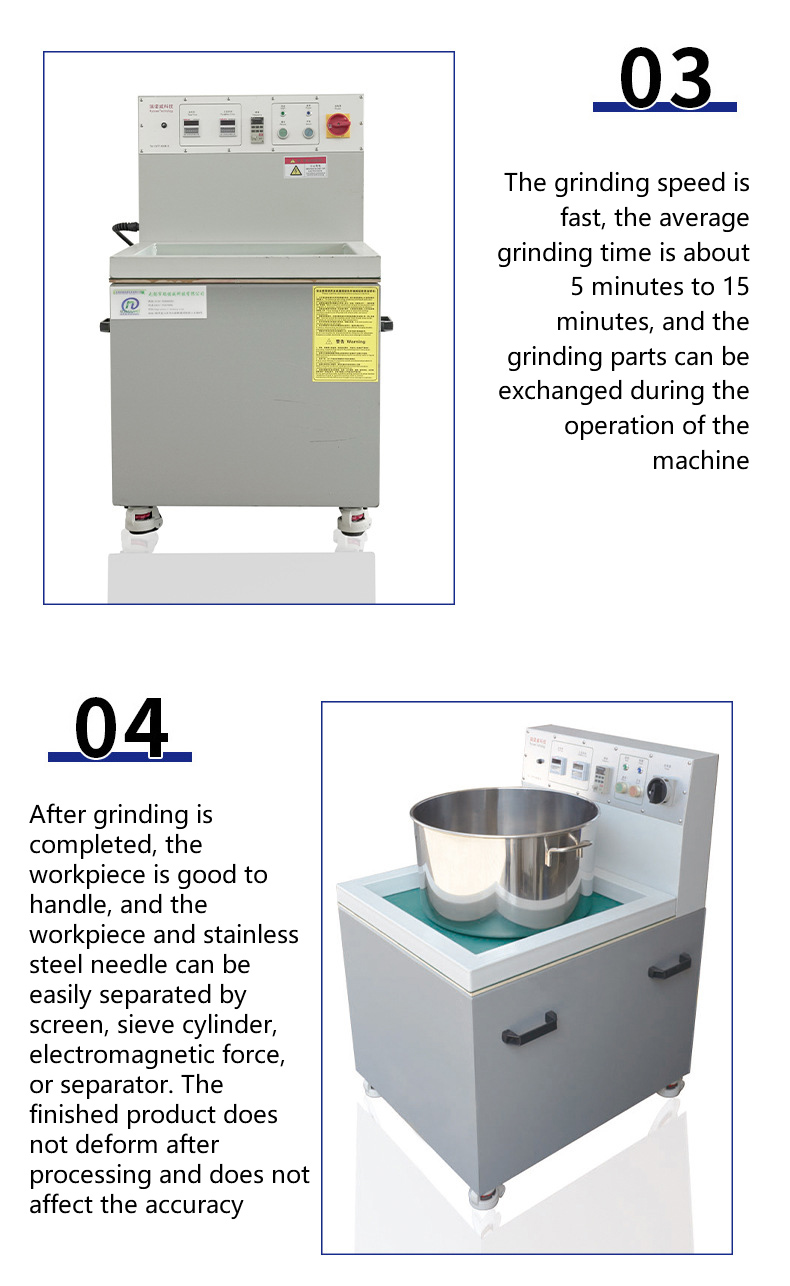

Machine running stability, high efficiency;

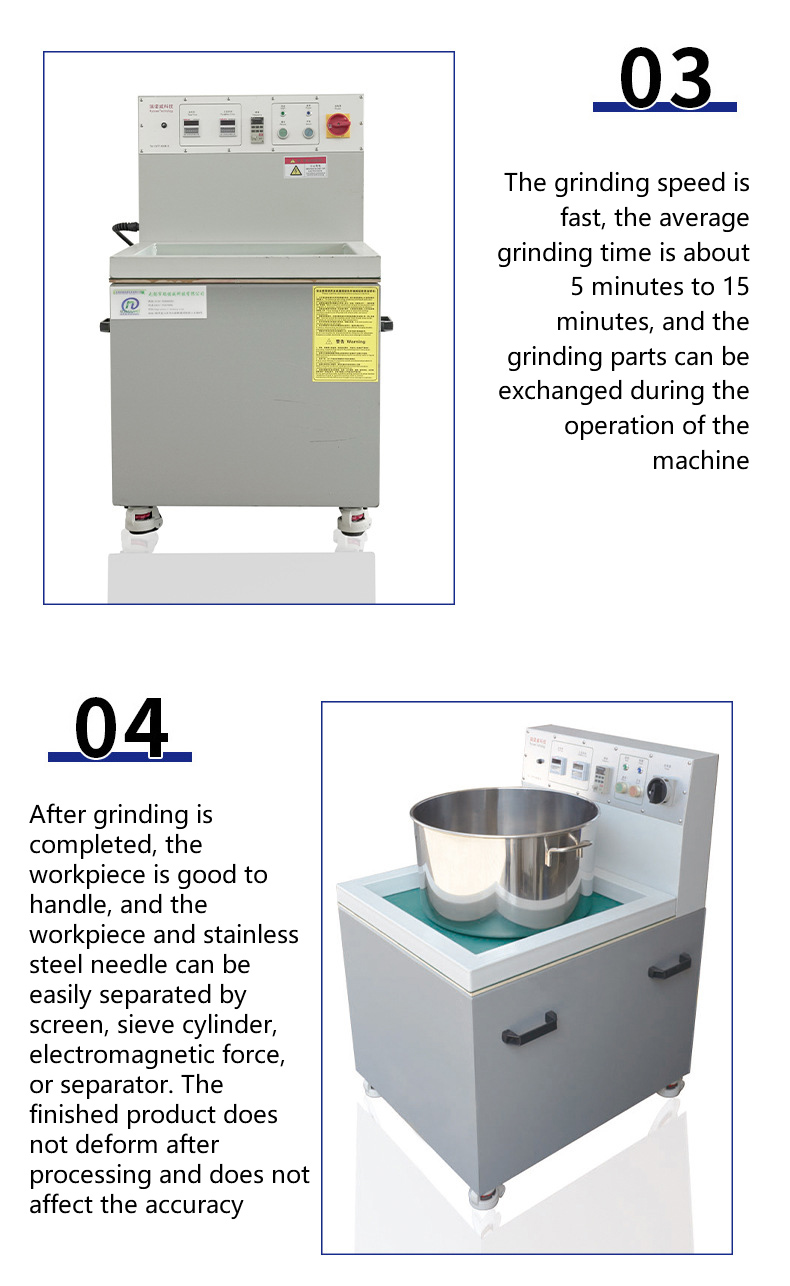

The grinding speed is fast, the average grinding time is about 3 minutes to 20 minutes, the replacement work is fast, and can be carried out in the operation of the machine;

Low cost, magnetic needle grinding material, very low consumption, the consumables for grinding fluid;

Body waterproof and moisture-proof design, simple and safe operation, completely free technology, can be operated by more than one person.

1. Precision stamping parts

2. Stainless steel parts, screws.

3. Magnesium aluminum die casting parts

4. Zinc-aluminum die casting parts

5. Precision spring, shrapnel parts

6. Electronic, computer, communication parts

7. Core, cutting, CNC automatic lathe parts

8. Aerospace, medical parts

Suitable for gold, silver, copper, aluminum, zinc, magnesium, iron, stainless steel and other metals and hard plastics and other non-metallic workpiece grinding and polishing. Such as: gold and silver jewelry, fashion accessories, metal parts of electronic products, precision bolts, metal parts with complex shapes, stationery accessories, instrument accessories